A cost- and time-effective solution for well intervention operations employs coiled tubing. Instead of removing the tubing from the well to fix a problem like a workover rig, coiled tubing is inserted into the tubing against the pressure of the well and during production.

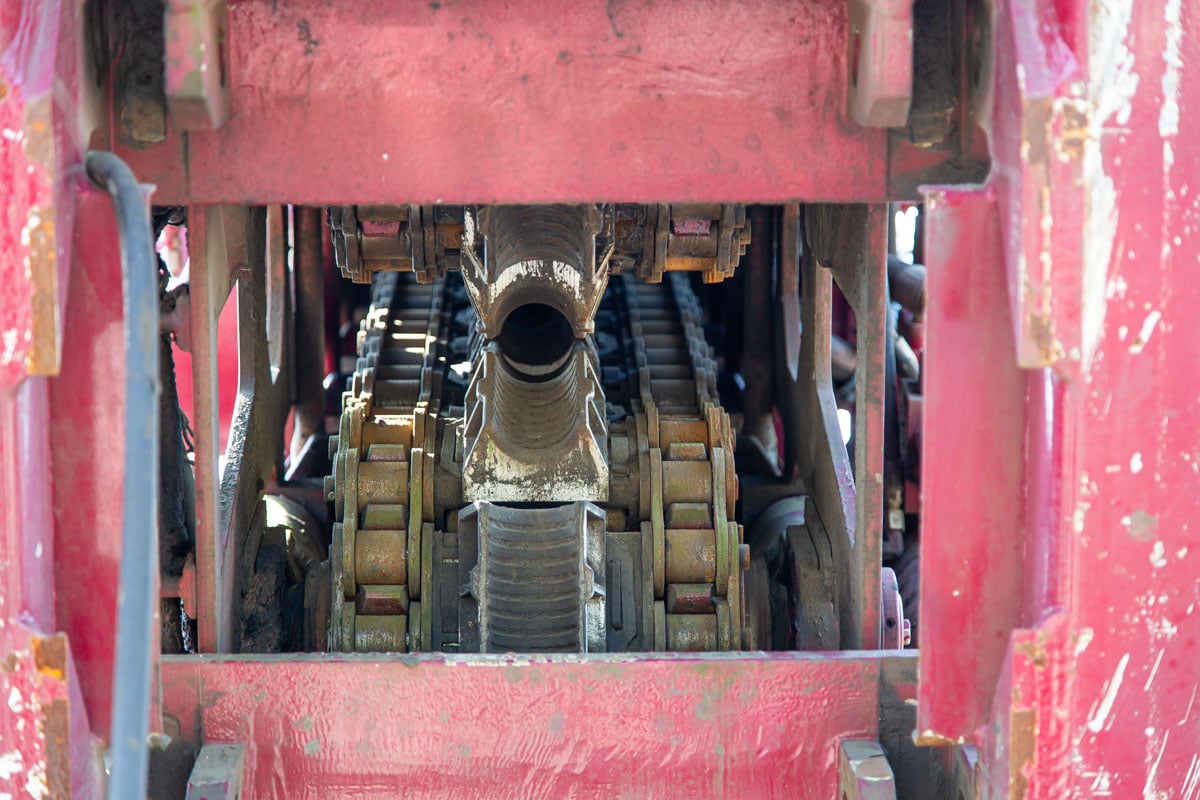

The coiled tubing is a continuous length of steel or composite tubing that is flexible enough to be wound on a large reel for transportation. The coiled tubing unit is composed of a reel with the coiled tubing, an injector, control console, power supply and well-control stack. The coiled tubing is injected into the existing production string, unwound from the reel, and inserted into the well.

The advantage of coiled tubing over conventional straight tubing Is the fact that coiled tubing does not have to be screwed together, and does not require a workover rig. Because coiled tubing is inserted into the well while production is ongoing, it is also a cost-effective choice and can be used on high-pressure wells.

Specs:

Length: 53′

Width: 8′ 5″

Height: 13′ 6″

Cabin features:

Custom built cabin manufactured with top of the line materials

Custom paint and full vinyl wrap

Low profile LEDs and textured floors

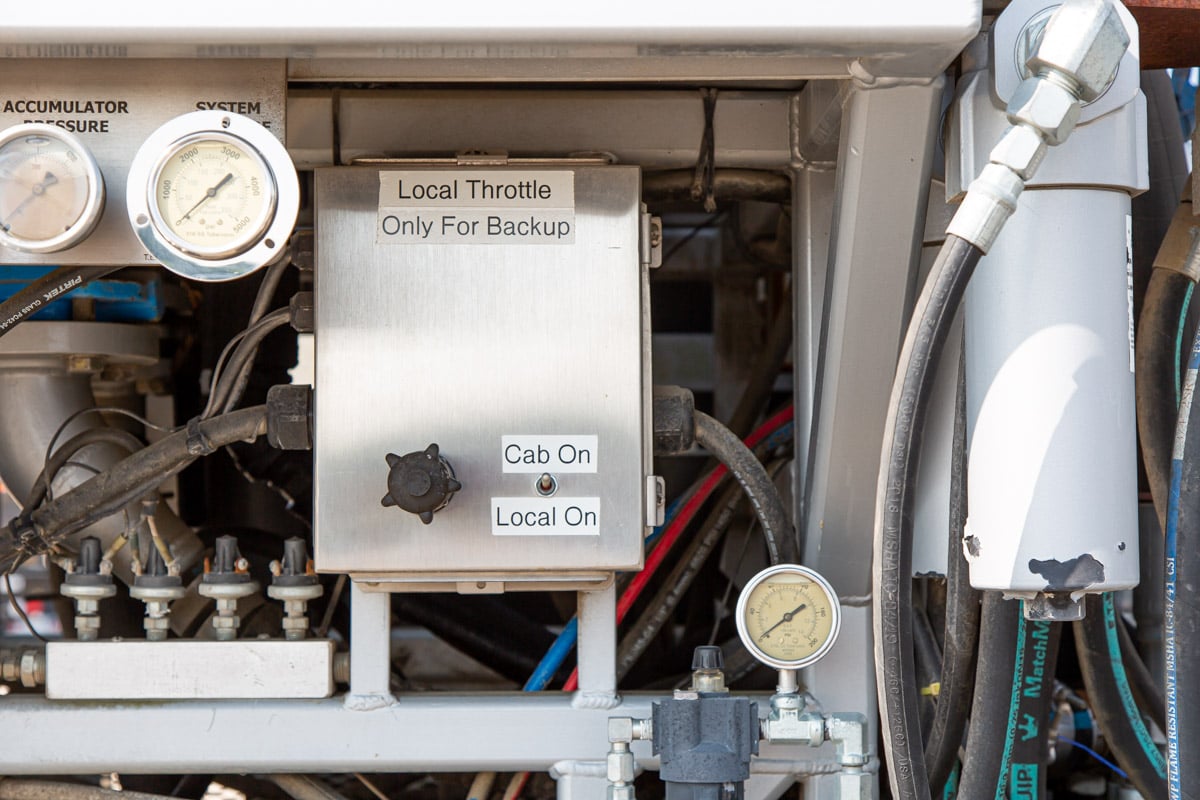

Fully customized console controls

Reel features:

Trailer mounted

Built-in tubing reel brake safety

Tubing data acquisition control system & software

Two-part drive gear to increase serviceability without reel removal